Best EN8D Carbon Steel Manufacturers & Suppliers in Mumbai – High Quality Carbon Steel Round Supply

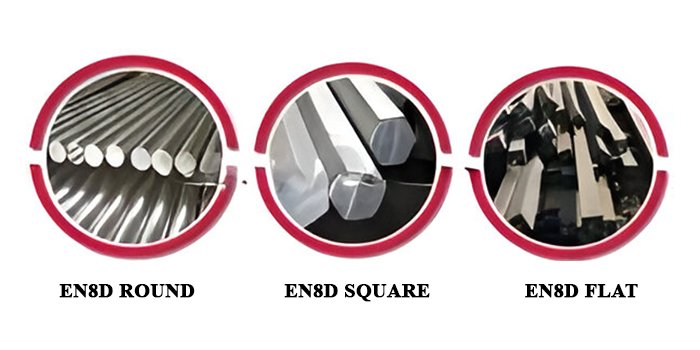

Looking for trusted EN8D Carbon Steel Round Bar Manufacturers & Suppliers in Mumbai ? We Titan Steel, Mumbai provide durable, precision-engineered carbon steel round bars for construction, industrial, and engineering needs. Get reliable quality, competitive prices, and timely delivery from leading suppliers in Mumbai.

EN8D Grade Introduction:

EN8D steel bar is a medium carbon engineering steel that offers improved strength and hardness over lower carbon steel grades. Its fair formability and weldability, along with good machinability, make it a versatile choice across various industries. While EN8D performs well in forging and heat treatment processes, those needing higher strength or specific properties often opt for alloy steels when EN8D or similar grades don’t meet the application needs.

EN8D Grade Application:

Common applications of EN8D steel round bars include gears, shafts, axles, bolts, studs, crane wheels, and various machine components.

EN8D Equivalent Grades:

| Standard | BS | DIN | IS | EN | SAE/AISI |

|---|---|---|---|---|---|

| EN8D | 080A40 | CK45 | 45C8 | EN8D | 1040, 1045 |

Additional Grades We Offer:

Along with EN8D, we also supply other grades, including MS, EN1A, EN8, EN19, EN24, EN31, IS 2062, 42CrMo4, H11, D2, M2, and more.

EN8D Chemical Composition:

| Element | C | Mn | P (Max) | S (Max) |

|---|---|---|---|---|

| Content | 0.40-0.45 | 0.70-0.90 | 0.045 Max | 0.045 Max |

EN8D Mechanical Properties:

| Property | Value |

|---|---|

| Max Stress | 700-850 N/mm² |

| Yield Stress | 465 N/mm² (up to 19mm LRS) |

| Proof Stress | 450 N/mm² Min (up to 19mm LRS) |

| Elongation | 16% Min (12% if cold-drawn) |

| Impact KCV | 28 Joules Min (up to 19mm LRS) |

| Hardness | 201-255 Brinell |

EN8D Hardness:

EN8D steel typically has a hardness of 180-220 Brinell.

EN8D Heat Treatment:

- Tempering: Temper EN8D between 550°C to 660°C (1022°F to 1220°F) for about an hour per inch of thickness. Cool in oil or water after treatment.

- Normalizing: Occurs at 830°C to 860°C (1526°F to 1580°F), followed by air cooling.

- Quenching: Quenching in oil or water after heating will harden the steel.

EN8D Hardening:

Heat the steel to 820°C-860°C, then quench in oil or water to achieve hardness.

EN8D Tempering:

After quenching, temper immediately while the material is still warm. Reheat to the required tempering temperature and soak for 1 hour per 25mm of thickness (minimum 2 hours), then cool in air.

EN8D Physical Properties:

| Property | Value |

|---|---|

| Tensile Strength | 90,000 psi |

| Yield Strength | 50,000 psi |

| Elongation | 20% in 2” |

| Reduction of Area | 30% |

| Brinell Hardness | 180-220 |

EN8D Forging Properties:

Preheat carefully and then raise to 1050°C for forging. Avoid forging below 850°C. After forging, cool slowly in a furnace if possible.

EN8D Welding:

EN8D steel can be welded without preheating for sections up to 18mm thick using MIG wire (SG2) or a 7018 electrode. For sections thicker than 18mm, a preheat of 100°C (212°F) is recommended to prevent cracking. Post-welding annealing is advised to avoid breakage.

EN8D Normalizing:

Normalize EN8D steel at 830-860°C, followed by air cooling.

EN8D Annealing:

Heat slowly to 680-710°C, then allow it to cool slowly in the furnace to ensure annealing is complete.

Titan Steel & Engineers Related Products:

Carbon Steel, Alloy Steel, Bright Steel, Spring Steel, Die Steel & Tool Steel, Special Alloy Steel

For Visit us Maps

Supply Cities

- Mumbai

- Ahmedabad

- Amaravathi

- Ambattur

- Bangalore

- Belgaum

- Chennai

- Chittoor

- Coimbatore

- Dindigul

- Mysore

- Nellore

- Hyderabad

- Kochi

- Mangalore

- Tirupur

- Tuticorin

- Madurai

- Andhra Pradesh

- Karnataka

- Puducherry

- Kerala

- Tamil Nadu

- Telangana

- Visakhapatnam

- Kochi

- Kerala

- Hubli-Dharwad

- Karnataka